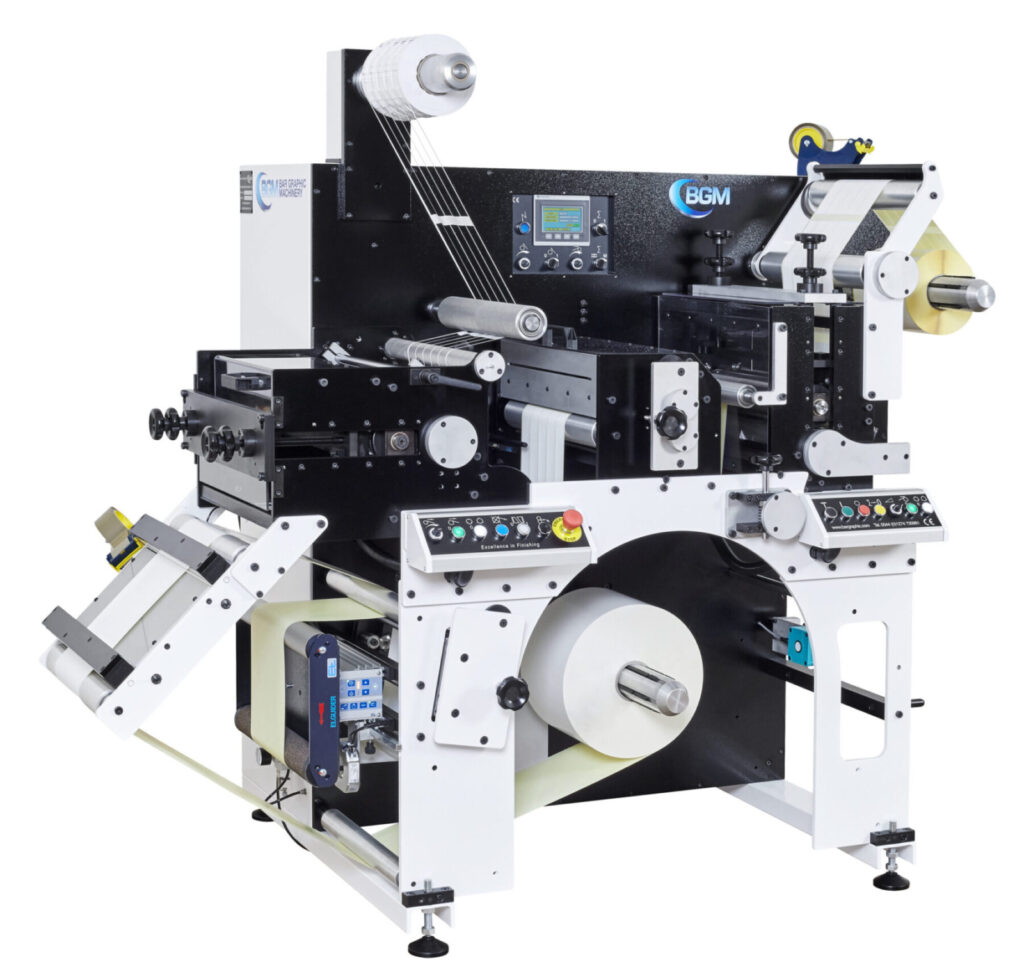

BGM Elite eDPSR Easy Load Die Cut and Perf Slitter Rewinder

Without doubt, this is the fastest, most cost effective, compact and robust, free-standing die cut & perf label cutting machine on the market.

The Easy Load Die Cut and Perf Slitter Rewinder has rotary die cutting speeds of up to 250m/min.

This machine can also be used as a conventional slitter rewinder, improving the finishing department’s capabilities.

High specification features commonly found on more expensive machines are fitted as standard, such as automatic unwind braking with adjustable roll end, reversible rewind & machine diagnostics.

A robust, fast, easy-loading die station enables the operator to effortlessly load the dies into the first station.

The weight of the die is supported by the bottom guide rail, which vastly improves operator set up time.

The second die station, designed for perforation, is fitted with a quick and easy to set ‘die cut to die cut’ manual registration facility.

The waste rewind is independently driven with variable tension control, ensuring perfect waste removal regardless of the label size or shape.

Adhesives cause no difficulties.

The touch screen enables the operator to set up the Die Cut and Perf Slitter Rewinder fast and efficiently.